Purposeful Power Monitoring for IT

Have you ever lost power to a server? Did it ever reboot on its own? Wouldn’t it be nice to prevent power outage to IT devices? If this is something you’ve experienced in the past, there are ways to simplify power monitoring and avoid some of the outages that can be caused by power issues. This article will focus on using power consumption data from a rack power distribution unit (rPDU) and how to simplify the process.

Many things can cause power problems. Have you ever experienced an outage due to a breaker tripping at home? I remember plugging in a fan one hot summer that tripped a breaker, shutting off the lights and my computer. This problem was quickly resolved. I just had to reset the breaker in the electrical panel and use a long extension cable to plug the fan into a socket in another room.

Imagine that happening in your IT infrastructure. It’s a nightmare for many reasons and remediation isn’t as simple as at home. Data centers are much larger, far away, and there are more breakers in every room of data centers.

Monitoring an electrical power system for a data center can be difficult but it doesn’t have to be. Some say it’s part science and part magic. It is hard to explain because physics is involved when discussing electricity. I’ll leave out the physics and logically describe how to gain the benefits of monitoring the power system. There are three main benefits that can be achieved:

I will focus on improving uptime since is the foundation before other benefits can be realized. After all, your on-premise data center houses the most critical application, so everything should be done to prevent outages.

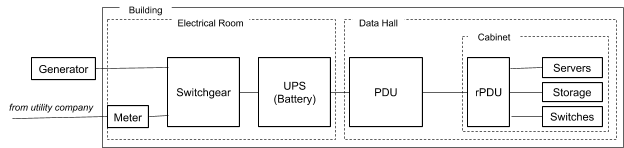

To increase uptime for the IT devices, some knowledge of the power system is required. Here is a simplistic, non-redundant overview:

All of the electrical power equipment must function properly in order for the IT devices to perform and deliver the always-connected, available anywhere applications to the digital world. Everything is built-in redundancy so the actual diagram should be much more complicated.

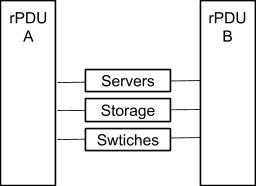

As you can see, IT devices get their power from the rack power distribution unit (rPDU). In the simplest form, they are larger versions of the power strip that you have on your desk. It connects to the power source and provides many outlets for the IT devices. They need to provide power and protect the IT devices. Modern IT devices require multiple power connections as they are power-hungry and also to provide redundancy within the device. As such, there are typically two to four rPDUs that feed power to IT devices. Two rPDUs are used for redundancy, just in case something in one power system fails.

The two main power attributes for our purpose are 1) “current” expressed in amperage (A or amp), and 2) “voltage” expressed using the same term, voltage (V or volt).

Now that we have a basic understanding of how IT devices are connected to the power system, we have to discuss a little bit of math. There are three rules to follow when provisioning the rPDUs:

With the rules above, only 40% of rPDU capacity should be provisioned realistically. Power current measured in amperage is the attribute used most when provisioning the power system. For example, with a 30 Amp rPDU, it should be handling less than 12 Amp most of the time.

Many rPDUs further segment within the unit. Each segment is commonly known as Branch Circuit. Typically, there are two to three branch circuits within a unit. Each branch circuit also includes a breaker to protect one circuit from another. These breakers are rated at 16 Amp (which is 80% of 20 Amp). This rating matches the capability of the C-13 and C-19 connectors that many IT devices use.

Branch circuit breakers will engage (trip) under two conditions:

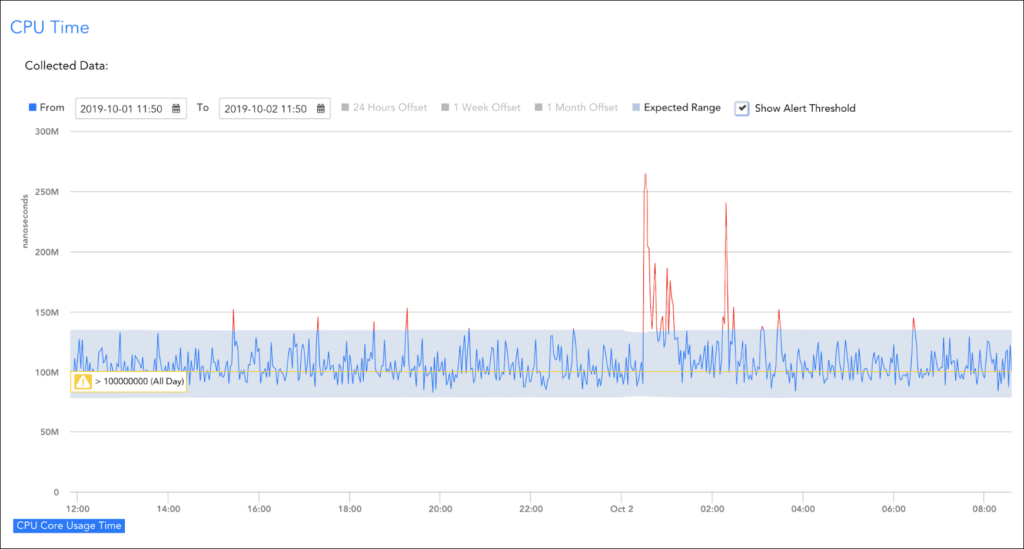

To avoid breakers tripping, I recommend these alert threshold settings power current:

When you get the warning alert, you should keep a close eye on it to make sure that the power consumption is not increasing over time. When you get the critical alert, consider re-provisioning or moving some of the IT devices off that branch circuit. Having historical data can assist in identifying where to move it.

So far we mainly discussed the power current attribute. Another important attribute is the power voltage measured in voltage (V). Power current and voltage work together but they behave differently. Most IT devices use power supplies that have their own performance requirements, expressed both in the amperage and voltage. When under-delivered, the power supply units cannot provide sufficient power to components within the IT devices which can cause an outage.

NOTE: Many IT devices will report the power consumption. Make sure to look for input (not output) of their power supply to compare to power measurements from the rPDU.

Power voltage does not vary significantly within the rPDU. Monitoring voltage and comparing it to the requirements of the power supply is critical. Most IT device power supplies will have a range of 208V to 240V. Unlike amperage, the voltage should be monitored so it does not go below the minimum requirement.

To avoid issues with the devices power supply, I recommend these alert threshold settings for power voltage:

The power supply and its requirement from the vendor behave differently, let’s call this sensitivity. The sensitivity of the actual voltage that might cause the power supply to fail will vary between units and models but this is a good starting point.

If any of the alerts are triggered, keep an eye on it, and if it occurs regularly, contact an electrician to resolve the issue. Low voltage is commonly a problem with the source where rPDUs get their power. Typically, a floor-standing PDU is a source. It handles higher power so an electrician is needed to investigate the issue.

Many rPDUs with monitoring capabilities support SNMP, which is great news. The bad news is that ObjectID needed to implement my recommendations is not standardized, so it requires a little investigation to determine which OID to use.

Here is a sample SNMP OIDs for some of the vendors:

| Vendor | Branch Circuit Current | Voltage |

| APC (Schneider Electric) | .1.3.6.1.4.1.318.1.1.15.4.2.3.1.5.a a = xPDUBranchBreakerTableIndex | .1.3.6.1.4.1.318.1.1.15.3.1.4.1.2.a a = xPDUMainInputVoltagePhaseIndex |

| Eaton | .1.3.6.1.4.1.534.6.6.7.5.4.1.3.a.b a = strappingIndex b = groupIndex | .1.3.6.1.4.1.534.6.6.7.5.3.1.3.a.b a = strappingIndex b = groupIndex |

| Geist (Vertiv) | .1.3.6.1.4.1.21239.5.2.3.3.1.4.a a = breakerindex | .1.3.6.1.4.1.21239.5.2.3.3.1.8.a a = breakerindex |

| Raritan (Legrand) | .1.3.6.1.4.1.13742.6.5.3.3.1.a.b.1 a = pudid b = breakerid | .1.3.6.1.4.1.13742.6.5.3.3.1.a.b.4 a = pudid b = breakerid |

| Server Technology | .1.3.6.1.4.1.1718.3.2.7.1.7.a.b.c a = towerIndex b = infeedIndex c = branchIndex | .1.3.6.1.4.1.1718.3.2.2.1.11.a.b a = towerIndex b = infeedIndex |

NOTE: refer to vendor specific Management Information Base (MIB) for details

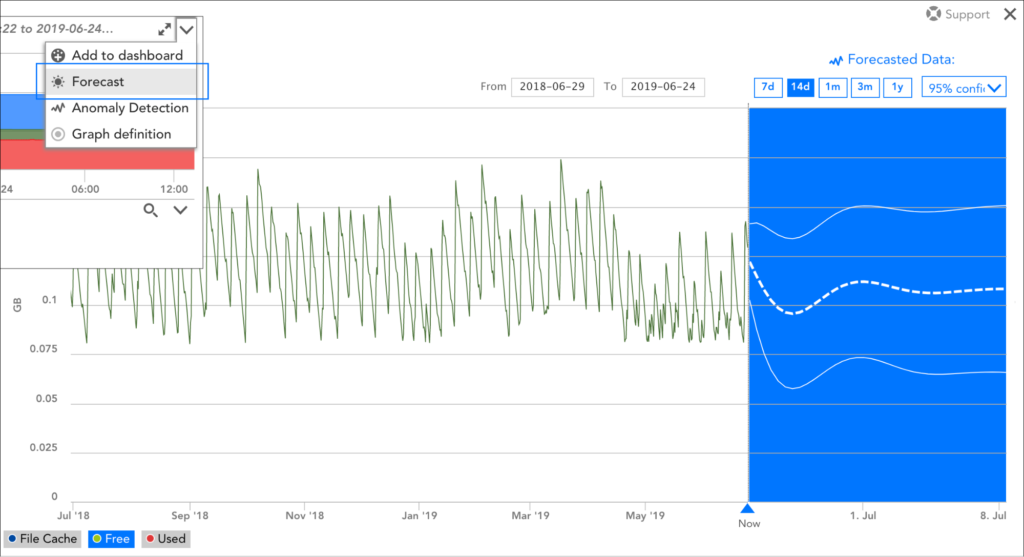

LogicMonitor can simplify monitoring electrical power system. With automations and deeper insights into power consumption data, taking the proper action at the right time can help in avoiding outages related to electrical power issues. Here are some feature highlights that have a direct impact on power monitoring:

As you can see, preventing potential outage caused by the electrical power system can be easily implemented purposefully using LogicMonitor. We make it simple to add rPDUs as a monitored resource and apply alerts and analyze collected data. As the saying goes, you set it and forget it. If you are interested in learning more about LogicMonitor’s capabilities, connect with your customer success manager or attend a weekly demo to see LogicMonitor in action.

© LogicMonitor 2026 | All rights reserved. | All trademarks, trade names, service marks, and logos referenced herein belong to their respective companies.